No products in the cart.

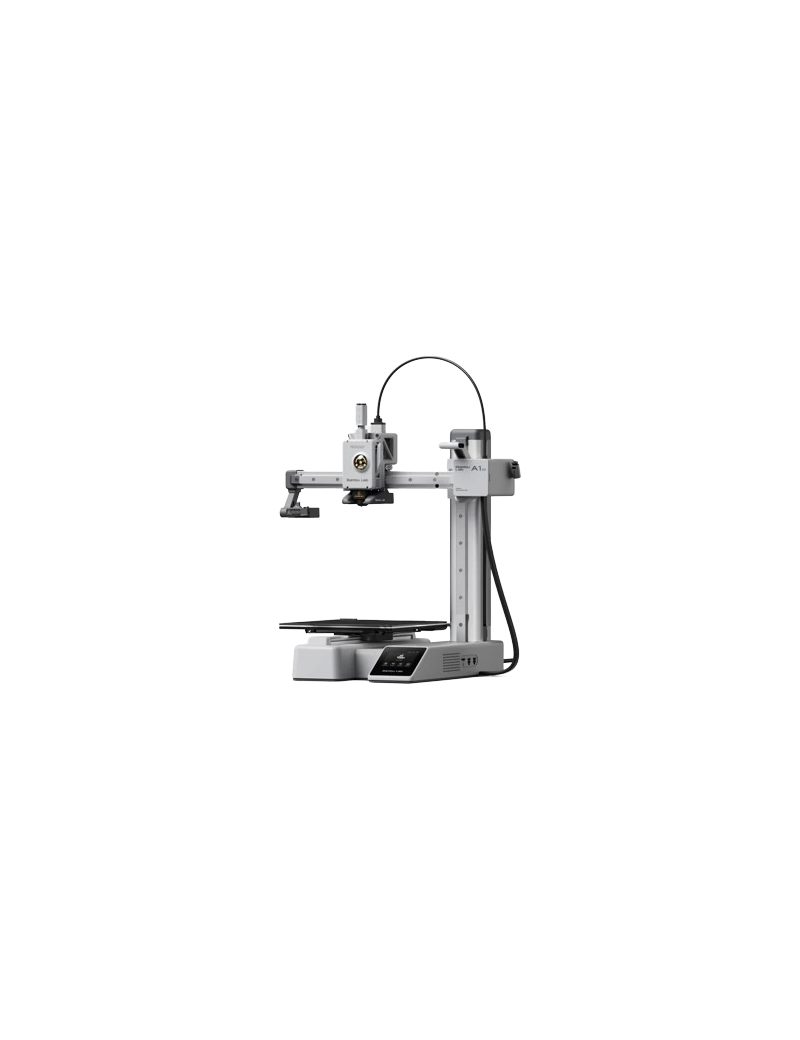

The Bambu Lab A1 Mini 3D Printer is a game-changer in FDM 3D printing, redefining flow control. It utilizes a high-resolution, high-frequency eddy current sensor to precisely measure nozzle pressure. The A1 mini comes to you pre-assembled, pre-squared, and pre-tuned with precision. It only takes about 20 minutes to set up for your first print.

Highlights

The Bambu Lab A1 Mini 3D Printer is a game-changer in FDM 3D printing, redefining flow control. It utilizes a high-resolution, high-frequency eddy current sensor to precisely measure nozzle pressure. The cutting-edge algorithm dynamically adjusts the flow rate based on sensor data, ensuring unrivaled printing accuracy.

The A1 mini comes to you pre-assembled, pre-squared, and pre-tuned with precision. It only takes about 20 minutes to set up for your first print.

A1 mini handles various calibrations all by itself. It meticulously calibrates the Z-offset, bed-level, vibration resonance and nozzle pressure for EVERY print job, automatically.

A1 mini probes the bed with the nozzle to measure the absolute z-offset. No need to stick a paper as reference.

A1 mini has sensors in toolhead and heatbed. One of the very first bed-slinger printers to run auto resonance calibration on both X & Y axes.

First of its kind, A1 mini runs the nozzle pressure based flow dynamics calibration algorithm. No need to draw any pattern or get any manual pick & match involved, A1 mini handles Pressure Advanced calibration automatically.

A1 mini can check the belt tension automatically through the vibration frequency calibration. If the belt is loose, the HMS system will notify you to use the auto belt tensioner to set the belt to the right tension.

The A1 mini revolutionizes flow control in 3D printing. It utilizes a high-resolution, high-frequency eddy current sensor to measure the pressure in the nozzle. Our algorithm actively compensates the flow rate according to the readings to extrude with accuracy.

Full-metal Rails, Rigid frame, nozzle pressure sensor, accelerometers, powerful MCU, and above all, an advanced motion control system that utilizes these features to print a 14-minute benchy with quality and following all the speed benchy rules straight out of the box without using specialized filaments.

All-new quick swap hotend design, the hotend pops in and out with just 1 clip.

Active Motor Noise Canceling and Silent Mode can bring down the noise level to under 48 dB, making A1 mini one of the quietest 3D printers on the market, so you can take a nap while your printer is working hard.

| Construction an Technical Details | |

| Usable Filament Diameter | 1.75 mm |

| Max Nozzle Temperature | 300 ºC |

| Open Filament System | Yes |

| Recommended Printing Speed Max | 500 mm/s ( |

| Build Area | 180 mm x 180 mm x 180 mm |

| Build Plate Temp Max | 80 ºC |

| Build Plate Surface | PEI |

| Build Chamber During Process | Open |

| Build Chamber Heated | No |

| Filament Chamber Closed | No |

| Extruder Number Of | 1 |

| Installation Space / Requirements | |

| Total Mass Overall Dimensions | 347 mm x 315 mm x 365 mm |

| Total Weight | 5.5 kg |

| Max Power Consumption | 150 W |

| Voltage | AC: 100 V240 V (50-60 Hz) |

| Equipment | |

| Emergency Shutdown | No |

| Hepa Filter | No |

| Door Sensor | No |

| Door Lock During Print | No |

| Filament Runout Sensor | Yes |

| Filament Clogging Sensor | Yes |

| Power Loss Fail Safe | Yes |

| Touch Screen | Yes |

| Camera | No |

| Connection | |

| SD Card | No |

| USB Port | No |

| Ethernet Port | No |

| WLAN | Yes |

| Accuracy | |

| Shipping | |

| Shipping Box | 385 mm x 430 mm x 430 mm |

| Shipping Weight | 8.2 kg |